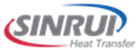

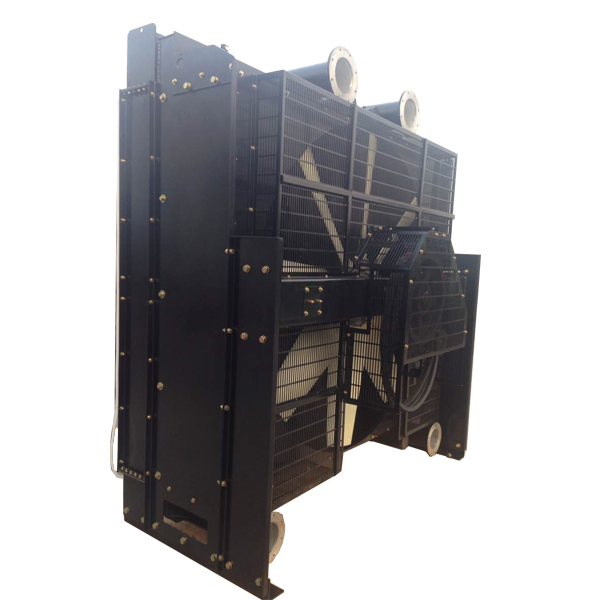

Product Name: Generator Genset 4006-23TAG3A Radiator

Product description: Generator Genset 4006-23TAG3A Radiator

Product details

Sinrui specializes in technical research, product design and manufacturing of diesel generator set water tanks and aluminum plate-fin coolers.

Different from other domestic water tank manufacturers, the water tanks we manufacture have the following advantages:

1. It can meet the matching requirements of high-power diesel generator sets: we have imported special numerical control equipment from the United States according to the matching requirements of large-scale water tanks. At present, the matched generator sets are more than 800KW, and the length and width of the water tank core set we manufacture can exceed 3 meters , Can meet the matching needs of generator sets above 2000KW;

1. Excellent heat exchange performance: Our water tanks with the same size core group have superior heat exchange performance than those of other domestic manufacturers;

1). In the process design, our core group adopts the tube-sheet structure, and the imported CNC equipment is used to punch the fins and tubes, and the tubes are arranged in a staggered manner. It is conducive to the flow of air between the fins, and the heat release of the cylinder jacket water is fully strengthened;

2) In the selection of materials, we use a copper heat sink (the thermal conductivity of the material at normal temperature is 330Kcal / h ℃), compared with the brass heat sink used by other domestic manufacturers (the thermal conductivity of the normal temperature is 93 ~ 130Kcal / h ℃); with better heat transfer performance.

3) In the assembly of the core group, we use imported assembly platforms to ensure that the spacing of the fins is uniform, which effectively reduces the wind resistance and is conducive to the flow of air between the fins; to ensure the combination rate of the cooling tube and the fins during the stringing process , Conducive to heat dissipation.

4) In the core group baking, we use high-purity tin to ensure the welding strength of the cooling tube and the heat sink. According to the experiment, the combination rate of the water tank cooling tube and the heat sink is more than 98%, while other domestic manufacturers The combination rate of the water tank cooling tube and the heat sink is about 70% to 85%.